Uchungechunge Lomshini Wokwenza Izinzipho

-

Umshini wokwenza izinzipho we-D50 onesivinini esikhulu

Umshini wethu Wokwenza Izinzipho Osheshayo wakhelwe ukuletha ukusebenza okuphezulu, ukhiqiza izinzipho zekhwalithi eyingqayizivele ngokungaguquki. Izinga layo lokukhiqiza elisheshayo liqinisekisa umthamo omkhulu wokukhiqiza, okuvumela amabhizinisi ukuthi ahlangabezane nezidingo ezikhulayo zemakethe ngaphandle kokuyekethisa ikhwalithi noma imikhawulo yesikhathi yokulethwa. Kusukela ezinkampanini zokwakha kuya kuma-workshops wokwenza izinkuni, umshini wethu ufanelekile kunoma yiliphi ibhizinisi elidinga izipikili ekusebenzeni kwabo.

-

Umshini wokuphakela kazibuthe

I-Magnetic loader iyisisetshenziswa esikhethekile sokudlulisa izinto ezinensimbi (njengezinzipho, izikulufu, njll.) ziyise endaweni ethile, esetshenziswa kakhulu ekukhiqizeni nasekuhlanganiseni imigqa. Okulandelayo incazelo enemininingwane yesilayishi kazibuthe:

Isimiso Sokusebenza

Umshini wokulayisha uzibuthe ukhangisa futhi udlulise ama-athikili anensimbi endaweni ebekiwe ngokusebenzisa uzibuthe oqinile owakhelwe ngaphakathi noma ibhande lokuhambisa kazibuthe. Isimiso sokusebenza sihlanganisa ikakhulukazi izinyathelo ezilandelayo:I-adsorption yento: Izinto ezisansimbi (isb izinzipho) zisakazwa ngokulinganayo ekugcineni kokufaka komshini olayishayo ngokudlidliza noma ngezinye izindlela.

Ukudluliswa kazibuthe: Ibhande elinamandla likazibuthe elakhelwe ngaphakathi likhangisa ama-athikili futhi liwahambise endleleni emisiwe ngedrayivu yemishini noma kagesi.

Ukwehlukana Nokuthulula: Ngemva kokufinyelela endaweni eshiwo, izinto ziyakhishwa kusilayishi kazibuthe ngamadivaysi e-demagnetizing noma izindlela zokuhlukanisa ngokomzimba ukuze kuqhubekele esinyathelweni esilandelayo sokucubungula noma sokuhlanganisa. -

Umshini ojwayelekile wokugoqa intambo US-1000

Umshini wokugoqa intambo uyisisetshenziswa sokukhiqiza izinzipho. Kunezinhlobo ezahlukene zemishini yokugoqa intambo, enganelisa izidingo ezihlukene zemakethe zezinhlobo ezahlukene zokukhiqiza izinzipho. Umshini wokugoqa uchungechunge ulula, uyazwela, uyasebenza futhi uneminye imishini efanayo ayikwazi ukushintshwa.

-

Umshini wokugoqa intambo enesivinini esiphezulu US-3000

Umshini wokugoqa intambo uyisisetshenziswa sokukhiqiza izinzipho. Kunezinhlobo ezahlukene zemishini yokugoqa intambo, enganelisa izidingo ezihlukene zemakethe zezinhlobo ezahlukene zokukhiqiza izinzipho. Umshini wokugoqa uchungechunge ulula, uyazwela, uyasebenza futhi uneminye imishini efanayo ayikwazi ukushintshwa.

-

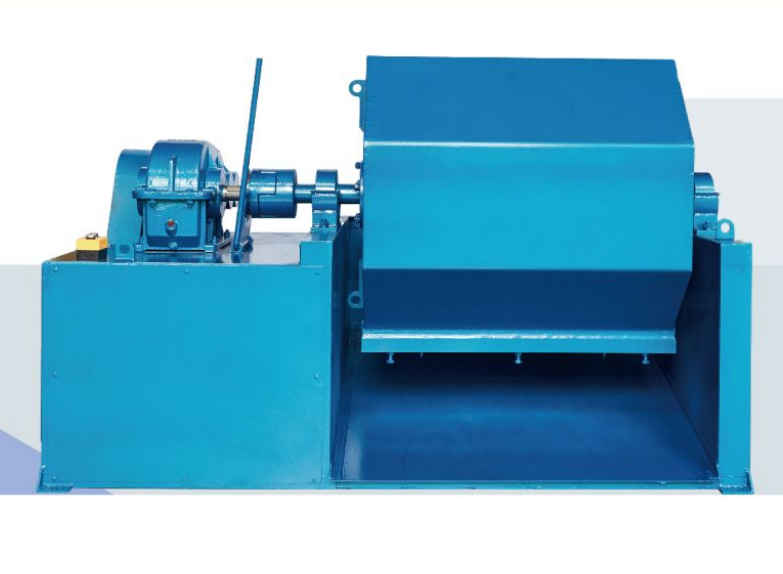

Umshini wokuwasha izinzipho

Umshini wokupholisha izinzipho ngocingo ubizwa nangokuthi umshini wokuwasha izinzipho. Isusa ama-burrs futhi ipholishe izinzipho ezicutshungulwe umshini wokwenza izinzipho ngokusebenzisa ukungqubuzana okujikelezayo kwesivinini esikhulu, futhi isetshenziselwa ukudelela nokupholisha izinzipho eziyindingilizi ezingakaqedwa ezisanda kukhiqizwa. Umshini wokupholisha izinzipho uyisisetshenziswa esikhethekile esibalulekile embonini yokwenza izinzipho.

Izinzipho zingcolile ngamanye amafutha uma ziwa emshinini wokwenza izinzipho ngokuzenzakalelayo. Futhi, amafu amaningi othuli ezipikili ezenza izitshalo. Ngakho sidinga aumshini wokupholisha izinzipho ngocingoukwenza izinzipho zocingo ezivamile zicwebezele.

-

Umshini Wokudweba Intambo Ekhanyayo Yomugqa Oqondile

Imininingwane Yobuchwepheshe Usayizi Owubukhulu I-Min Outlet Yokudweba Inombolo Isilinganiso Sokuncishiswa Isilinganiso Esijwayelekile Sokunciphisa Isivinini Isivinini Sokuncishiswa Kwamandla Ezimoto Isilinganiso Sokunciphisa I-Annealing Φ1200 Φ8mm Φ5.0mm 1-9 ≤ 20% 60% 120M/min 90KW Φ12KW Φ1mm 0000d 0 ≤ 20% 60% 240M/min 75KW 110KW 80db 60% Φ700 Φ8mm Φ2.6mm 4-13 ≤ 20% 60% 600M/min 30KW 45KW 80db 700db 700% Φ3mm 20% 60% 720M/min 18.5KW 37KW 81db 80%... -

I-Horizontal/Vertical Spooler

ivumela ukuqoqa ucingo ku-spooler. Ihlinzekwa nge-wire guide at variable pitch.

-

Umshini Wokudweba Izintambo Ezimanzi

Umshini Wokudweba Izintambo Ezimanzi

Ifanele ukudweba izintambo ezinamandla kakhulu, njengentambo yesondo, i-PV silicon cutting wire

-

Umshini Wokudweba Wezintambo Eziqondile LZ-900-1000-12000

Umshini Wokudweba Ngocingo usetshenziswa kabanzi ekusetshenzisweni kwezimboni, osetshenziswa kabanzi ekwenziweni kwemishini, ukucubungula ihadiwe, amakhemikhali e-petrochemicals, amapulasitiki, uqalo nemikhiqizo yezinkuni, intambo nekhebula nezinye izimboni.

-

Umshini Wokudweba Wezintambo Eziqondile LZ-350-400

Umshini Wokudweba Ngocingo usetshenziswa kabanzi ekusetshenzisweni kwezimboni, osetshenziswa kabanzi ekwenziweni kwemishini, ukucubungula ihadiwe, amakhemikhali e-petrochemicals, amapulasitiki, uqalo nemikhiqizo yezinkuni, intambo nekhebula nezinye izimboni.

-

Umshini Wokudweba Wezintambo Eziqondile LZ-200-250-300

Umshini Wokudweba Ngocingo usetshenziswa kabanzi ekusetshenzisweni kwezimboni, osetshenziswa kabanzi ekwenziweni kwemishini, ukucubungula ihadiwe, amakhemikhali e-petrochemicals, amapulasitiki, uqalo nemikhiqizo yezinkuni, intambo nekhebula nezinye izimboni.

-

Isiphakeli samagnetic

Incazelo Yenqubo:I-workpiece ithululelwa ku-hopper yami (nge-spring) kusuka kuhlaka lwezinto ezibonakalayo, futhi kukhona idivayisi yokudlidliza ngaphansi kwe-hopper. Idivayisi yokudlidliza isebenza ukuze isabalalise ngokulinganayo ucezu lokusebenza ku-hopper ebhandeni eliphakanyisiwe le-conveyor. Kukhona inkambu yakazibuthe eqinile ngemuva kwebhande lokuthutha, elimunca ucezu lokusebenza ukusuka ekugijimeni ku-trajectory ebomvu ukuya phezulu. Lapho inkambu kazibuthe enamandla ifinyelela phezulu, igaywa kabusha, futhi ucezu lomsebenzi luwela endizeni elandelayo yokusebenza yenqubo.